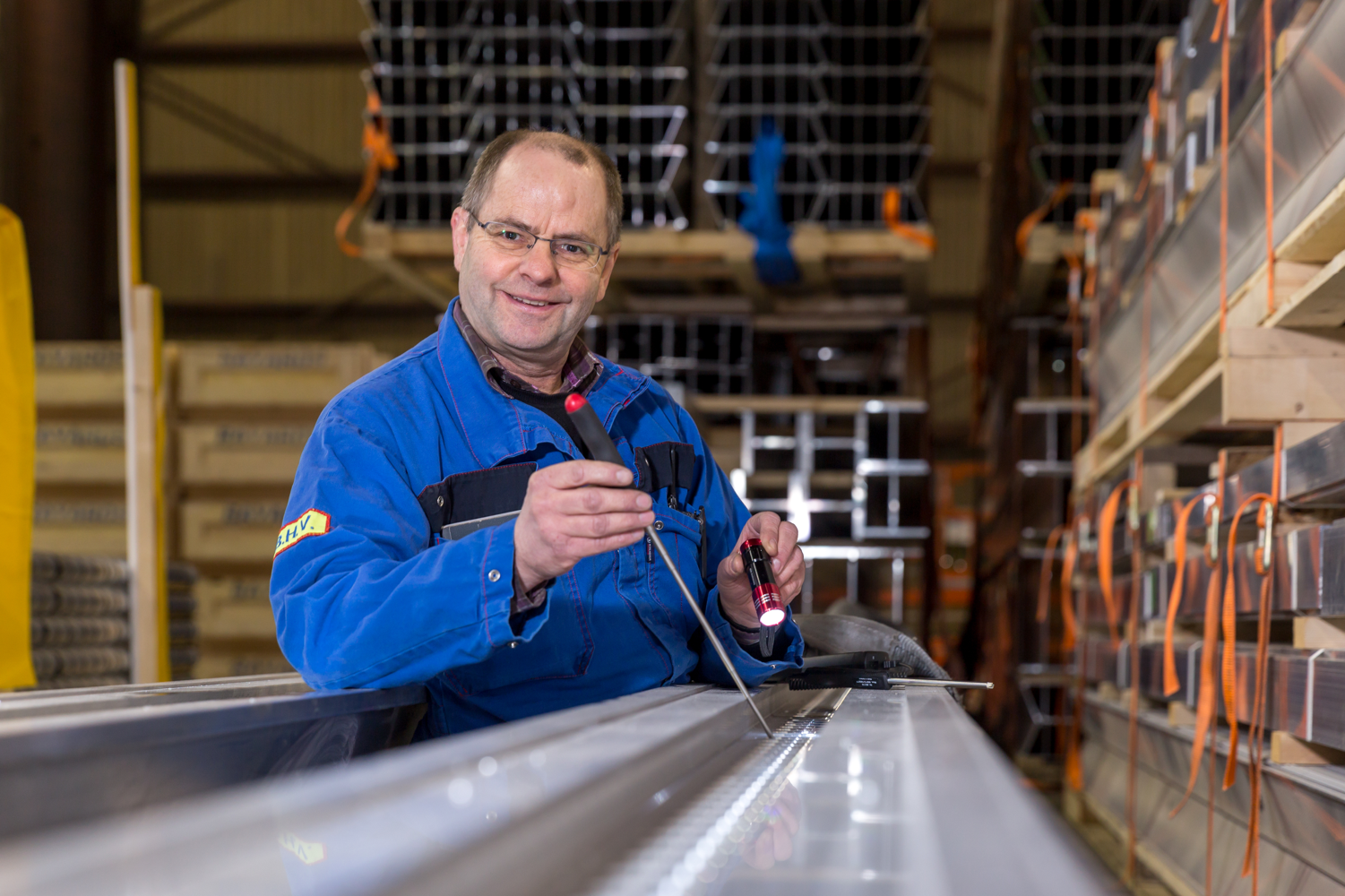

"My work is never monotonous and there is no lack of innovation at Bayards."

Peter Jelier

“I am welding coordinator at Bayards Dintelmond, which includes doing the visual weld inspection and making the welding lists. Coordination of welding research (ultrasonic, radiographic and penetration) is also carried out by me. A quite separate part of my work involves coordinating container transports around the world. Our products are often assembled on site locally under the supervision of a supervisor. To that end, all components are loaded in a container as efficiently as possible, everything having been carefully counted and checked. This also means that everything has to be documented. This requires you to liaise with project leaders, work planners and production team leaders and in order to send each and every one of the thousands of parts in perfect order, you have to work in a structured way so that requires quite a bit of teamwork.

Having worked in the steel industry for my entire career, I started working at Bayards in 2007. Changing from steel to aluminium was quite a stretch for me because my mind-set until then was 'can’t you only make cans out of aluminium?'. This was the first association I had with this material. That turned out to be quite a revelation for me! You can easily process aluminium: you can saw, drill and mill it with the added benefit that it is much lighter than steel. It is also much cleaner to work with because the material does not rust. Welding aluminium is no more difficult than welding steel, only the material behaves differently, so you do have to bear that in mind. My work is never monotonous and there is no lack of innovation at Bayards. Simply put, this a nice company to work for. Would I go back to steel? No way!"

Back to stories